24hr Media Things To Know Before You Buy

24hr Media Things To Know Before You Buy

Blog Article

24hr Media Can Be Fun For Anyone

Table of ContentsAn Unbiased View of 24hr MediaThe smart Trick of 24hr Media That Nobody is Talking About24hr Media Can Be Fun For EveryoneThe Best Guide To 24hr MediaThe 9-Minute Rule for 24hr Media

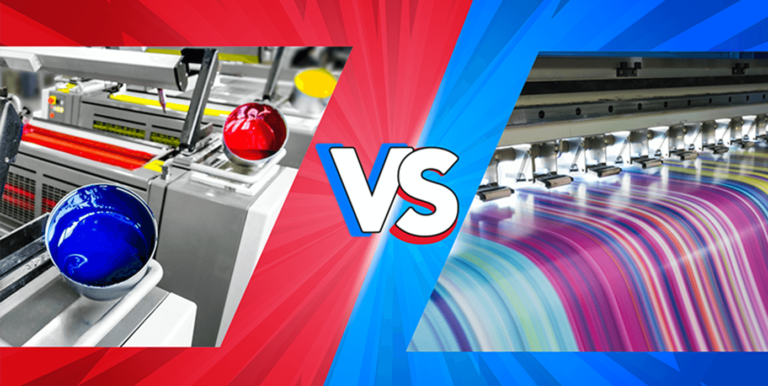

Advancements in print technology are transforming the interactions playing area when it pertains to quality, cost and innovative abilities. Countered printing and electronic printing are the major processes whereby print work are taken on both making use of four-color printing methods. Each option has its advantages, supplying different methods to meet the demands of diverse manufacturing projects.

Usually, this has been the most constant technique for specifically preserving shade matches, making it optimal for print runs that just need static printing such as pre-printed forms, brochures, flyers, business cards, and bulk postcard mailings. Due to the fixed nature of litho printing, it is not ideal for variable print pieces that will be mailed to private receivers such as declarations, letters, and personalized postcards.

Our 24hr Media Ideas

The most current advancements in print technology are aiding to bring several of offset's benefits into the digital printing globe really changing the face of modern printing! There are some vital distinctions in between Offset Printing and Digital Printing.

Today's electronic print equipment is amongst the most innovative on the marketplace. Here are a few of the greatest benefits of using digital printing: control the electronic print space, with full-color printing finished in one procedure and flawlessly printed directly from a print file. Without a prolonged set-up process, the calibration time of a specific work is shortened, adding to quicker print time and overall distribution.

The inkjet printing process has actually aided to reinvent the market along with the quality and rate of the outcome. The most up to date inkjet technology can print on typical countered stocks with boring, silk, and glossy coatings. Top notch electronic print coupled with software-managed color management methods adds optimum worth to publish items and makes production procedures a lot more reputable than balanced out.

Facts About 24hr Media Uncovered

(https://www.easel.ly/browserEasel/14556334)

Environmentally friendly and biodegradable inks and printer toners are additionally offered for more lasting printing. Digital print likewise removes the need to clean plates or blankets with hazardous chemicals you can check here at the end of the printing procedure.

Variable information assists businesses reach their precise customers and target market with uniquely-created and personalized content. As innovation enhances, the quality of electronic printing has come to be second-to-none, with higher detail, shade match capabilities and general precision. Without the demand to wash plates or make use of excess ink, digital printing is also less wasteful and usually a lot more eco pleasant.

("flexo"), include numerous make-ready steps to move an initial picture to a substrate.

Some Ideas on 24hr Media You Need To Know

Digital printing, with less moving items, is much more agile than offset in this regard.

Reduced set-up time conserves money on the front end. And considering that these are not enormous bulk orders, smaller companies can pay for to print without having to satisfy the greater and extra expensive print limits of traditional printing.

Make sure you team up with a printing and product packaging companion who has the right qualifications. While eleventh-hour printing and modification are a huge advantage, electronic might not always be the best approach for you. Counter printing has the advantage of cost-effectiveness with large print runs, specifically those with sophisticated decorative results and specialized finishes.

24hr Media for Dummies

Lithographic presses make use of two print platesa positive and a negativeto transfer top quality shade graphics onto an appropriate substrate. The favorable plate, with its smooth surface, draws in oil-based inks and pushes back water. On the other hand, the unfavorable plate, with its harsh appearance, absorbs water and pushes back oil. Rubber rollers are then made use of to move the image from the plate to the corrugated surface area.

Corrugated paper can sometimes prove to be a difficult surface to print on, yet Litho prints to a separate surface and is after that laminated to it, making it simple to publish high-quality photos. It can be extremely constant, also for lengthy runs. The a lot more you publish, the less expensive the costs come to be for Litho.

What Litho doesn't provide you is specifically what Digital does, personalization. Costly set up Longer turn-around No Variable Data Printing Smaller color range, colors can be much less intense Digital printing is the procedure of printing electronic photos directly onto the corrugated substrate using a single-pass, direct-to-corrugate technique.

Report this page